Regulars here will have already read my series of articles (here and here) about battling the ethanol demon – and casting him out of the fuel tank (and carburetors) of my ’76 Kawasaki Kz900. Well, I’m now in the process of doing the same to my ’83 Honda GL650 Interstate. The carbs are being cleaned – and the tank is being sealed.

But, I’m also doing another thing that was already done to the old Zed. I am re-jetting the Honda’s carburetors to compensate for the leaner E10 (10 percent ethanol) “gas” that I’m forced to feed her.

Here’s the deal on this: Ethanol was originally pushed into the fuel supply back in the ’80s (along with MTBE) as a way to reduce the exhaust emissions of the vehicles then on the roads – most of which were still carbureted and didn’t have computer-controlled fuel management and so could not auto-adjust their air-fuel ratios to accommodate different fuel mixes (and octanes).

Because E10 is 10 percent ethanol – and ethanol is less energy dense than gasoline – the effect (in an older vehicle with a carburetor and “fixed” jets) is a lean-running condition. This tamps down certain emissions, but a negative side effect is that lean-running engines tend to run hotter (and not as well, either). It’s bad for any engine to run lean – and hot – but it’s particularly bad for aluminum/air-cooled motorcycle engines to run lean (and hot).

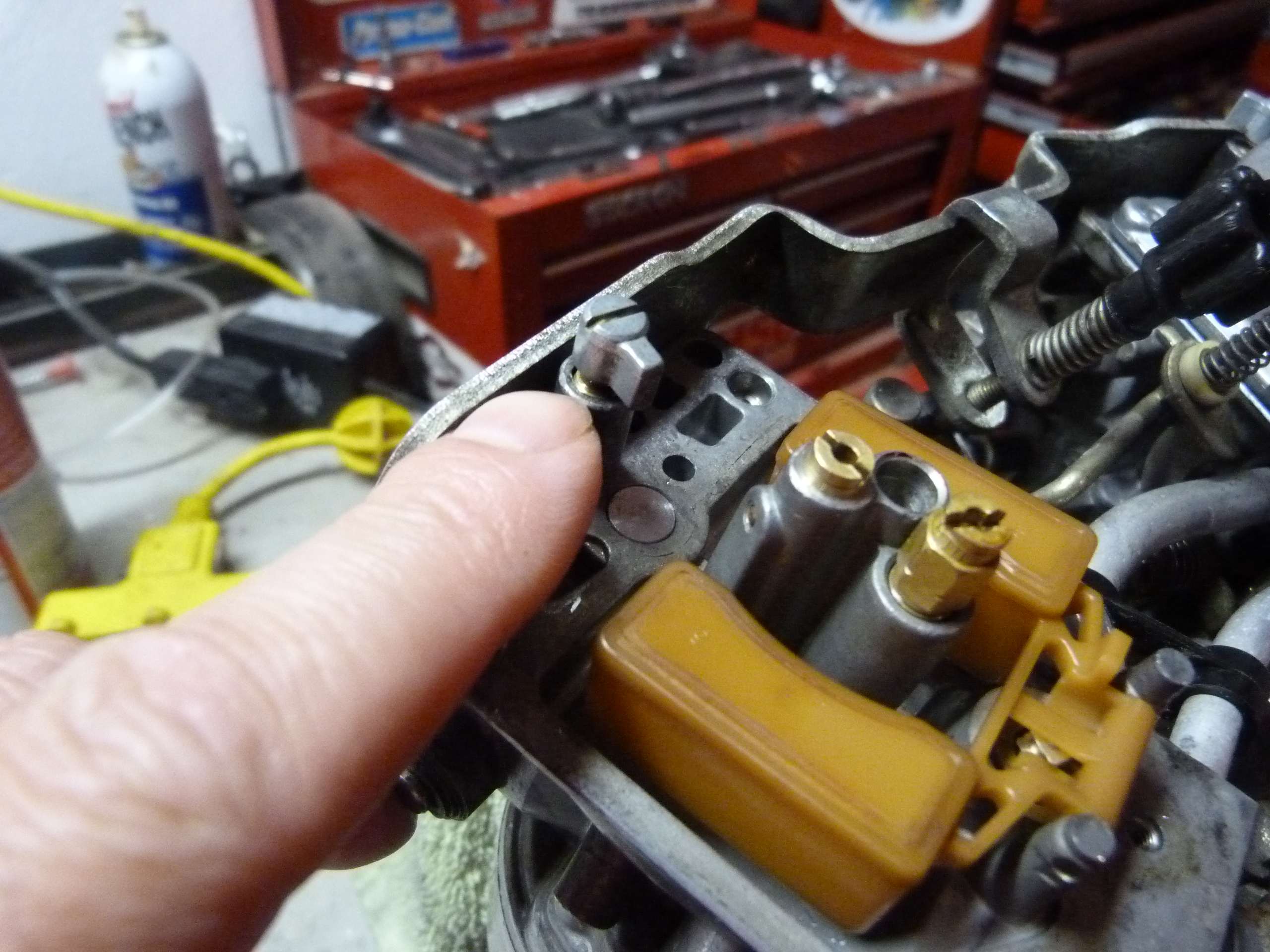

Now, the ’83 Honda’s engine is water-cooled, but I still prefer it not run lean – or too hot. I’d also like it to run as well as possible on modern fuels. Hence, as part of my ministering to it, I am going to try an experiment. The factory jets – and these GL650s (and, apparently, the related CX series) have Keihin carbs with a main and secondary jet and the expected pilot jet – are numbers 118 (main) and 78 (secondary) respectively. The pilots are – apparently – fixed in place and cannot be messed with, though the air screws are adjustable once you file down the limiter caps.

The usual procedure when up-jetting is to jump two sizes, though the usual rule is to do this only when the bike’s engine has been modified – pod air filters, an aftermarket exhaust, etc. My bike is factory stock. The only difference is the “modified” fuel it’s fed. Remember: Circa 1983, Honda engineers assumed their motorcycles would be fed gasoline. Not gas less 10 percent gas.

The carburetors were jetted accordingly.

But 30-plus years down the road, the fuel is very different. In effect, running the GL650 on ethanol is like running it at high altitude. It is necessary to make some adjustments.

So, I have ordered new (richer) jets, sizes 120 (mains) and 80 (secondaries). I bought ’em here. The prices are very reasonable – and they have a pretty huge selection of both Keihin and Mikuni jets.

While I wait, I de-rusted and sealed the tank and also gave the carburetors a thorough cleaning. Many hard-starting, poor-running issues can be corrected by cleaning (and adjusting) the carbs. If you’re dealing with stuff that’s 30-plus years old, it’s to be expected that varnish/gunk/rust is possibly gunking up the works. Slides get sticky, needles and seats wear out, floats rot and leak. The ethanol in gas accelerates this process. One thing we’re probably all going to have get used to – those of us who dabble with old stuff – is more frequent carb maintenance, including partial/total teardowns to keep them clean internally. It also helps – when you’re doing a rebuild – to use a kit that contains ethanol-compatible parts, especially o-rings and rubber diaphragms/cups (accelerator pumps, etc.).

Oh, yeah – about those air screw limiter caps. Honda installed them to placate the Feds, to make it harder to “tamper” with the factory settings. That is, to richen things up from the factory lean setting. A tab prevents the screw from being turned in either direction more than about half to three-quarters of a turn unless you first remove the fuel bowl. That makes it impossible to do the fine adjustment, which requires that the engine’s running as you turn the screw in (and out) while noting the rise (and fall) of engine RPM.

The fix is easy. You can either file down the tab – or use a grinder to file off the little ridge cast into the fuel bowl that the tab buts up against. Be careful – proceed slowly – whichever path you choose. Just file off enough material to permit the screws to rotate completely with the fuel bowl installed. Now you can adjust the engine to make it run optimally – as opposed to running the way Uncle wants.

Throw it in The Woods?

If you value alternatives to the mainstream media, please support independent media.

Our donate button is here.

If you prefer to avoid PayPal, snail mail is fine. The address is:

EPautos

721 Hummingbird Lane SE

Copper Hill, VA 24079

eric, you only have to look at the tests lubricants are put through, or in the case of many, not put through since Amsoil has such severe testing Mobil and others won’t allow the results of their oil to be published. Simply take the temps at which synthetics in general will perform and what they do for seals and that tells you everything you need to know. Each year more vehicles are mandated synthetic lubricants. I wouldn’t use anything but synthetics in air-cooled engines, or any other, and most gear boxes. Over 20 years ago many light trucks mandated synthetics in their transmissions and sometimes gear boxes. The powerful engines of vehicles such as the Corvette has mandated synthetics for well over 20 years and many European cars have as well.

If you buy a new car and the dealership insists on servicing it themselves(“free” oil changes), you can call a number to get experts(lawyers unfortunately for the most part)to talk to the service people and change their mind in a hurry. Some lubricants are well above the factory synthetic and have testing to prove it when some shop foreman says it has to be “their” lubricant and no other. If you desire to use Amsoil, they have a staff dedicated to informing the dealers of the specifics of the law. I’m not pushing any brand here, I just know this from experience. Maybe some other brands have this too but I’m not aware of it.

I’m sorry to say my last lawnmower(not my Lawnboy)dropped a cylinder on a hot day. I doubt this would have happened with a good synthetic oil. I just kept putting off changing it over and it bit me on the you know what.

Amen to all that, Eight!

I’ve had particularly good results – obvious ones – going with synthetics in manual gearboxes (the ones that do not use ATF, of course). Much smoother operation – especially on very cold days. Less noise – and no problems with any of them, yet.

eric, synthetic transmission fluid is also light years beyond petroleum. It brought my wife’s cars tranny back to life and is still going. I used it in my diesel pickup’s transfer case. That and synthetic gear lube will return the “instant” on 4WD instead of making a few rounds of the tires before locking in. The only thing I’ve used with a pushbutton 4 WD system is a ’13 Dodge diesel. The hell that pickup gets makes me think any time could be its last to engage before needing parts. I despise that entire thing. What was so bad about a shifter? It always worked? I can understand getting away with using it for the dumbed down crowd but if you have a 4WD pickup you should understand that 2H, 4H, N, 4H, 4L. I operate equipment with “international symbols” and don’t have a clue till I select something what the hell it is I’m turning off or on.

Back in ’72 a new John Deere tractor had those symbols. I asked if Mexicans or Canadians could decipher it. The guy who owned it said I don’t know but I may have to find one to figure it out, must be smarter than I am. And now they’ve been changed to the point they make no sense. I always thought I had a pretty good imagination but most of these symbols leave me clueless. I finally figured out that “coolant” had been changed to a double ripple like thing. I wish they’d change oil to a pumpjack or XOM symbol, now that would be international.

Yup!

The stuff works wonders in used/older equipment. Drain the case of the old goop, refill with synthetic – and it’s transformative. Well worth the cost, which is not excessive in my opinion (relative to the cost of a new/rebuilt transmission/transfer case).

PS: Glad you’re not having issues posting. I’m closely monitoring the situation and hope to have all the regulars “inside the fence” within a day or so.

And “F” the spammers.

eric, I had a bike I changed to aftermarket air cleaners. It leaned it out to the point low end torque went to nothing. I realized it would be the death knell in this heat. I’m not expert at all on bikes so I may be pissing into the wind here but I used a numbered bit set where there’s just minute amounts between bits and re-drilled the primary jets. It seemed to fix it but I then started getting fuel mileage I wasn’t supposed to get. Of course the heat gauge wasn’t any help since I’ve never seen one on an air-cooled bike. Just for the record why in hell isn’t that an option….at any price? It’s not like no thing has ever had a heat sensor on an air cooled head. I grant you it’s rare but if it’s expensive enough to rebuild there will be something there for that. But in most cases though, the machine is simply re-engineered with a liquid cooled engine.

Maybe it’s just me but it seems fairly insane to run engine oils with viscosity’s that look like gearlube. Yes, I’m sure Harley’s were once great bikes for some climes but I’ve seen them seize for decades in Tx. heat. Of course it’s not confined to a single brand but much more so for big cubic inches and little in the way of heat transfer ability. I recall in the early 70’s when VW tried to make the Beetle into something it could never be and picked up stranded people along the roads. “I don’t know, it just lost power and quit”. Sorry people, you can hang out here at my house till your friends can come get you and bring something to load your car on. Cold beer anyone? Yes? Too bad your shiny new air/conditioned VW with four people and their luggage couldn’t have asked for one.

Excuse me if I seem miffed but Chuck, the truck and it’s C12 Cat took a dump on me today. I had lights, beepers and flashers and a limit of 1300 rpm. Once again, we’re speaking of an engine not designed for the fuel it’s forced to use. Take off the pressure cap on the radiator and it blows bubbles. YOU know what’s wrong and so do I but big brother doesn’t care and there are a great majority of diesel engines out there not designed for the new no-lubrication fuel, i.e., low-sulfur. Unlike you , it’s owners didn’t want to run the added lubrication products that would have avoided this if used regularly. You can’t make a gearhead out of someone whose concern is always the bottom line “as they see it”. I suspect many thousands of dollars later they might catch on. I’m looking for another job while they’re trying to get up to speed. OTOH, this is the second time for this engine. Nope, I suspect they won’t ever get it.

Hi Eight,

Replacement jets for most carbs are usually pretty easy to get – and pretty cheap, too. I’d go that route before drilling out the stockers.

I agree on the weird rarity of a temp. gauge on most older (and many newer) bikes. Not even my ’03 ZRX has one. It has a fuel gauge instead.

I added an oil pressure gauge to my Kz900 – it previously had just the idiot light.

I also run only premiums synthetics in my bikes. It may be of dubious value in a street driven car, but bikes are another story. Especially air-cooled bikes that spin to 9,000 RPM!

make sure the tank sealant does not clog up any internal screens while wet, otherwise fuel wont come out of one or more outlets to the petcock- in my case, I have no ‘on’- only reserve until I clear it. I have an 85 suzuki gv1200 I am servicing for a blown head gasket among other things.

Yup!

On the GL, there’s a sleeve/screen filter that fits into the threaded nipple on the underside of the tank (the thing the fuel tap screws onto). Remove this (the sleeve/screen) before cleaning – much less sealing – the tank!