It’s hard to imagine a 7.4 liter V8 that only made 200 hp. It did. Back in ’76, the year my Pontiac Trans-Am (which I still have) left the Norwood, Ohio line. And my car was pretty much top-of-the-pile. The typical V8 of that era offered up perhaps 170 hp. Some less.

Seems sad, right?

Sure.

Modern fours a fourth the displacement make that much hp today. Some of them a lot more than that. And the Trans-Am’s 0-60 run – just under eight seconds, if you were good with the Super T-10 – is only about twice as long as it takes a new Mustang GT or Camaro Z28 to get there.

But it wasn’t all bad – and some of it was very good.

It depends on your perspective.

You may not have got a lot, power/performance wise, back in the day. But what you did get (a simple V8, no computer) had potential. So does the new stuff, of course. But the old stuff’s potential differed in that it was easily (and inexpensively) accessed. This mattered if you were a kid in high school – where the love affair with cars used to get serious.

Doubling the 455’s horsepower from the factory 200 to 400-plus is about a $1,500 job in today’s money, if you’re decent with a wrench. What it takes is a new camshaft (about $200 today for a kit with lifters) and maybe some new heads – or machine work done to the heads you’ve got.

The factory exhaust system was usually garbage; but unlike today, back in the day there were just pipes (cheap) and mufflers (ditto) to replace and a good set of headers cost maybe $250 because they didn’t have 02 sensors or need to be EPA/CARB certified and you could install them with basic hand tools and some determination.

Teenagers on a part-time, fast food job McBudget could swing this. And so, they did. Maybe not all at once, but over a summer or two? Sure. I know it was doable because I did it and so did my friends. We worked on cars and so came to love working on cars. Which led to most of us loving cars. We bonded with them. They were ours.

It was the difference between getting an already assembled display quality model ship and building the thing yourself.

One looks good, the other made you feel good.

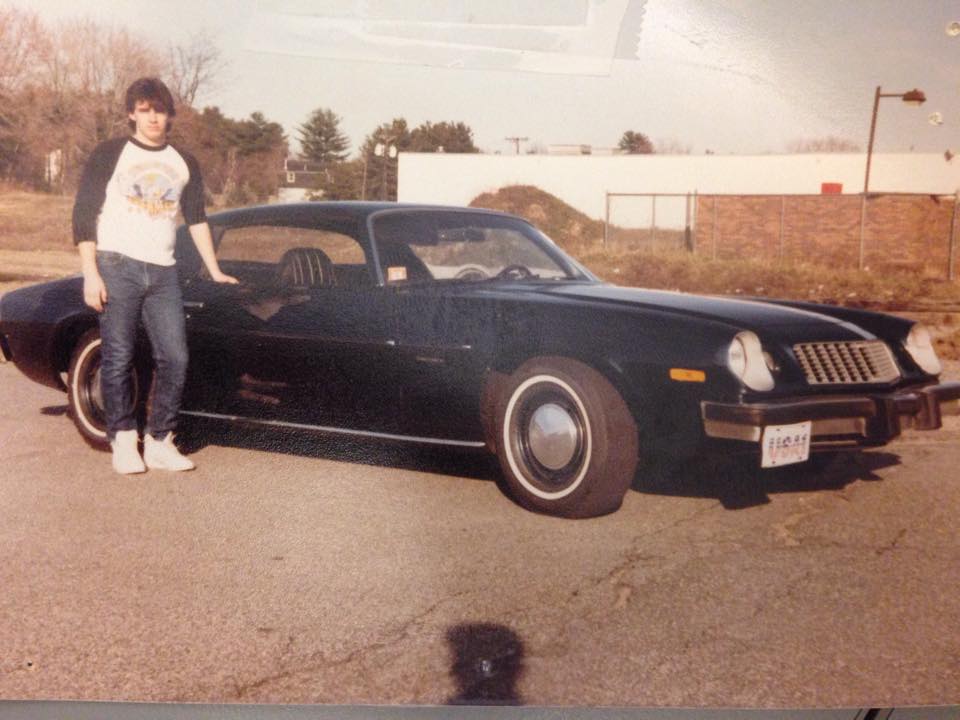

Anyone (with the money) can buy a new SS. Only you – a 17-year-old! – had that 383 stroker small block you put together in the garage, then put in your ’78 Rally Sport yourself, super tuned yourself… got just right, yourself.

Everyone knew your car. Which wasn’t like anyone else’s, no matter how much money they threw at it.

We’d change out steering wheels (you could do that, before cars came with air bags), add gauges (most cars didn’t come with them), were constantly fiddling and fooling around with them.

Even minor changes yielded major improvements. This kind of thing is immensely gratifying when you are 17-years-old.

You’d start with something that didn’t cost anything, like flipping the air cleaner lid over. Maybe one of your buddies told you about this. A gnarly hissing/vacuum sound ensued. The car suddenly seemed a lot tougher.

Maybe the next step – after studying Hot Rod magazine (instead of Spanish) would be fiddling with the ignition timing. All you needed was a $20 timing gun from Pep Boys and a 9/16 distributor wrench to loosen the hold-down bolt. You’d carefully turn the distributor by hand and watch the timing mark on the balancer advance or retreat, note the change in pitch of the engine. Set it, then drive it – see how it felt. Sometimes, it felt better. Sometimes, it knocked – too much advance! – and back to the driveway pad for some adjustment.

With your own two hands.

Feel it, see it.

The tactile, mechanical experience – the communion with the car – was wonderful. And it was nearly free. (If you had a buddy with a timing gun, it was free).

Similarly, modding a carburetor.

You could see how it worked. It was a contraption, not a computer (whose workings you cannot see). Put it on a bench, take it apart. Put it back together. Hopefully, successfully. Eventually, you would. Or, go from two to four barrels. Maybe add a spacer. Swap out the stock intake for a hi-riser. This sort of thing appeals to teenage boys, who have a natural affection for things mechanical. How does this work? What would make it work better?

You fine-tuned the thing. You tried different jet sizes, altered the float level, maybe hogged out the needle and seat. Experimented. None of this cost much money.

It was a great way to spend a Saturday afternoon, too.

Then came Saturday night.

Cruise the local fast food joint or mall with your friends. Show them what you did; see what they did. Confer, boast, admire. Dream and scheme. Sometimes, we raced.

Damn, we had fun!

EPautos.com depends on you to keep the wheels turning! The control freaks (Clovers) hate us. Goo-guhl blackballed us.

Will you help us?

Our donate button is here.

If you prefer not to use PayPal, our mailing address is:

EPautos

721 Hummingbird Lane SE

Copper Hill, VA 24079

PS: EPautos stickers are free to those who sign up for a $5 or more monthly recurring donation to support EPautos, or for a one-time donation of $10 or more. (Please be sure to tell us you want a sticker – and also, provide an address, so we know where to mail the thing!)

I wonder if kids still “cruise” anymore. I certainly did in the 80s. Believe it or not there was no alcohol or anything else around. We just rode around, the Burger King was a favorite spot. Innocent times. I feel kind of sorry for today’s kids that have no mechanical experience and are completely glued to their screens and toxic social media.

I also was a product of the 60’s in So Cal, running my B stock 390 Galaxie ([email protected]) at Lions, San Gabriel, Fontana et al. I never got over my need for speed so at 74 I just built a 1986 S10 with a aluminum head, Edelbrock equipped 350/350TH. It is really strong, speed thrills.

Hi Alymar,

I just installed a functional flapper door in the shaker scoop of my ’76 Trans-Am!

Eh, I think about this stuff all the time, having grown up in the ’60s. I was CONSTANTLY screwing with my cars. The only information source was my dad, my older brother-in-law, or buddies. No internet to bail you out!

Swapping engines one time, I had to convert the car’s generator system to the alternator system that was on the new engine. I knew nothing about it, but a work-buddy did; he drew a diagram and I followed it. Who needs the internet? Haha.

When I bought a 2007 Corvette two years ago (after a 40+ year break from hotrodding) reality struck — it was a whole new world. It’s all electronic crap now, which I knew nothing about, but am learning piece by piece. So far (car has 28K miles on it) everything works. Someday it won’t.

But the basics haven’t changed.

Hi Andy,

Yup, there’s an engine in there… somewhere!

While there were plenty of inaccuracies in the Fast & Furious franchise, some of what they said seems to carry the philosophy these days “Throw about 10 grand at it, and you’ll have a fast car!”

Not so much about mechanical details, other than some generic plug-in phrases designed to sound good… like an automotive version of the movie “Hackers”

EP, great post. Reading this article made me feel like I was out on the driveway on my back under dad’s 69 GS 400 all over again. I remember vividly flipping the air filter cover over and going out for some test runs down to the DQ. Thanks for the memories.

My pleasure, Dude!

“after studying Hot Rod magazine (instead of Spanish) ”

Trump 2016, because the workers at my local autoparts barely speak english.

It is too bad there are too many government regulations out there that prevent the another mass production of the classic cars people want in terms of body style. Who would not like to drive around in a carbon fiber body and ergonomically upgraded version of just about any classic car made in the 20th century. I’m sure there is a market and it better yet, it would employ people to do something. But no, we can’t have that now, can we?

Here’s one for us Mopar fanatics…a “trick” which is relatively unknown, but can solve “bogging” problems in both “A”, “B”, and “RB” engines. Despite good tuning and carefully calibrated carburetor setting, a “bog” on initial acceleration was still noted.

For those of us who still utilize the vacuum advance in stock distributors, the vacuum advance is adjustable by utilizing an allen wrench through the vacuum advance opening on the distributor (where the vacuum advance hose attaches to.

Turning the wrench clockwise allows the vacuum advance to “pick up” sooner while a counterclockwise turn decreases the effects of vacuum advance…

This “adjustment” is not documented in any of the Mopar literature, but it works…

All is not dead. from what I see a lot of kids these days are customizing Honda Civics the way your generation did with 1970s Detroit V8s. Turbos, camshafts, wheels, steering wheels, spoilers, you name it and they’re doing it.

Hi Stefano,

I agree they were doing this in the ’90s and early 2000s… but it seems to me the interest has waned. Probably because the economy sucks and people in their 20s are feeling the pinch more than most.

There are quite a few youger guys that bring their mitsu/honda/toyota/nissan/subaru etc to the track near here. 3/4 of them are turds but there are several 11 and 12 second stock appearing cars that show up regularly.

Hard to get the power down in a fwd, all the ones I have seen running 12s or better were awd , fwd typically spin like mad on the launch. I recall a certain Civic that would one wheel peel up to the 3-4 shift around 80+ mph. Trap speeds on it were 117/118 mph IIRC. ET was only like 13.7x….

Hi DirtyBob!

In re: ” fwd typically spin like mad on the launch…”

Shoot I have that problem also!

My Trans-Am is hopeless (as far as hooking it up) coming off the line. You have to ease into it and then lay it down. That’s what happens when you have 500 ft.-lbs. of torque and 15-inch wheels! I’d put something larger on the car – and the car would be much quicker and a whole lot safer – but I love the looks of the factory wheels and besides, going sideways is almost as much as going quickly!

Slicks ( http://www.jegs.com/i/Mickey-Thompson/672/3054/10002/-1?parentProductId=746895#moreDetails ) will take care of a lot (if not all) of that wheelspin. That old TA is leaf rear suspension right? If slicks dont cure it then a set of caltracs (or slapper bars if you dont mind losing some ground clearance) should get it to dead hook.

Drag radials are another alternative http://www.jegs.com/i/Mickey-Thompson/672/3754R/10002/-1?parentProductId=753925#moreDetails

Also worth noting that you would likely need a driveshaft loop to run the slicks and pass tech at a dragstrip. The rules are probably different for the radials.

I have gone as far as trying some American Racer G60 (DOT legal) tires on my fwd regal gs but didn’t get enough starting line improvement over street tires to care. Same tires that work fine for a mid 12 sec 70ish mustang fastback (60′ times in the mid/low 1.6x range).

The difference is they need to do it with credit cards.

This article brought back a lot of great memories. In the late 70’s I had a 1970 Chevelle SS with a 396 (402). My job in high school went to buying headers, aluminum intake, a 650 Holley. The good stuff. When the water pump or anything else that had little to do with more horsepower broke it was a trip to the junk yard.

We always experimented. I would borrow my friends Holley 750 with vacuum secondaries to see how it would perform versus my Holley 650 double pumper. Head to the local “speed shop” and buy different springs for the centrifugal distributor weights.

For decades I had my distributors “tuned” for the engine. It makes a lot of difference, esp. with water/alcohol injection. A mechanic I knew had the special machines to change timing through the rpm band. It could help even if the engine was fairly stock with add-ons like different intakes, headers and full flow exhaust, etc. Once GM had the electronic distributor I never had another with points.

I’ve replaced the points in all my old stuff with the Pertronix kit – and have nothing but kind things to say about it. (I still have points in the ’75 S1 because it’s a triple and you have three sets of points and no one makes a simple replacement for this set-up. It’s a weird bike!)

I am a big fan of the GM HEI distributor. It produces a strong spark but it’s still a pretty simple device and very, very reliable as well as easy to tune.

Hi Owen,

Me too. Good times. I miss them!

Sorry, but I won’t look back fondly. Yes, the old stuff was easy to work on, but that was because you HAD to work on it. I still remember dad cursing up a storm when trying to get the car started on a cold Christmas Eve so we could head to midnight services (I think that’s when I learned the definition of irony). The stench of exhaust from a too-rich carburetor dumping fuel into an engine that doesn’t know what to do with it all, so it just throws it out the tailpipe. Rust and Bondo.

The thing is, just about everything has evolved to be more complicated and less repairable. This is an artifact of progress. I spend a lot of time working on electronics. My first computer was a trainer that was programed in machine language and had LEDs on the data and address lines so I could watch what the microprocessor was doing. It was very expensive and not very useful. But I could fix it if I needed to. Stuff evolved, and now we have iPhones and GUIs and even simple disposable items like memory cards are far more complicated than that 1970s era computer. Do I care that I can’t repair an SD card? Does it really matter (maybe)? Do I look back and wish I could use my iPhone performed the same as that microprocessor trainer? HELL NO!

Early manufacturing is usually fairly easy to understand. Iron and steelmaking was fairly simple, just get a lot of charcoal and dump it into a stone pile with iron ore in the middle. Cook it for a few hours and puddle out the liquid metal into pigs. Show that same ironworker a modern blast furnace and he’ll see the same process (well, technically he’ll see the Bessemer process, but he’ll likely understand it after an explanation), but there’s no way he’ll be able to run the thing. As production evolves and scales, the specialization necessary increases exponentially. This is the basis of the modern corporation of course.

And keep in mind products aren’t built by humans anymore. They’re built by robots. Robots aren’t humans, so manufacturing has to adapt to what a robot can do, not what humans can do. Think of a house. A house is built by humans with a little help from machinery like cranes and lift platforms. Using robots to build a house this way would be a disaster. But if you design a house with the idea of it being built by robots it will likely be unrepairable by humans. Electronics are already mostly that way (this year I’m resolved to learn how to do surface mount soldering). Cars are getting to be that way, and it’s only a matter of time until everything is that way. It really should be the political discussion of our time (what will we do when labor and products are basically worthless), but instead we get more crazy.

Designing stuff to go together is different than designing stuff to come apart. Most cars go together great in order of assembly. They’ll even come apart well more times than not in the reverse order. The problem is the desire not to take everything out that went in after the part you need to replace. Case in point, a rusted brake line on my Mazda. Real PITA. Why? Because right after the unit body’s paint was dry the lines for the rear brakes and the fuel system was installed, as a sub assembly. Then everything else. Now I had to replace a brake line with all that everything else in the way while separating and then installing the new one into the subassembly of the fuel and brake lines.

The temperature swings where I live play havoc with carbs. What worked yesterday might not work today. Sometimes I think a piece of equipment has something wrong with it but then I get an ideal weather day and it starts up and runs perfect. It’s the nature of carbs, they don’t change unless someone changes them. So now we have collector cars with carbs that only see nice days. They don’t have to function over a 120F range any more. They are also not daily driven so the way they drift away from optimal doesn’t happen happen like it used to. The result is people forget the pain.

Unrepairable, costly complexity is progress? First you don’t lament the passing of the good old days. Then you make a good case that our gadgets are too complicated and that we should be somewhat concerned about it. What golden mean are you swinging for?

” First you don’t lament the passing of the good old days. ”

The good old days were good, indeed, but lamenting a simpler time when we didn’t yet see how badly we were being herded and controlled isn’t quite the same as lamenting the passing of older tech that had to pass, is it?

This is subjective as hell, I realize… but:

For me, the “golden mean” was the late 1980s/early-mid 1990s. You had fuel injection, but it was (typically) simple (often, TBI). You had overdrive transmissions, but not dual clutch/SMG boxes that cost $5k to replace.

Maybe just two air bags – or better yet, none.

A specific example of a “golden mean” vehicle: Late ’80s/early ’90s Chevy pick-up with a TBI 350 and a five-speed manual.

Those twin clutch DSG transmissions ARE a problem unfortunately. That trans is a slow-fuse time bomb just waiting to grenade (usually not so long after the warranty expires). Once it does that you will find that “it’s a non-repairable item, sir”. There are no spare parts and no technical data available even if you do know a shop that would try to rebuild it. Actually, it is worse even than that, they are deliberately designed not to be able to be fixed whatsoever. Here is an example for you.

Recently a young lady I met purchased a nice German sporty car with a DSG transmission. Drove nice and the gearshifts were impressively swift. The car was second hand, dealer purchased and out of warranty. She had it for 10 months and then the transmission failed. She took it to the dealer who sent it to a transmission specialist. The specialist requested the dealer fetch up the technical data from the German manufacturer. Meanwhile he got to work puling the trans and dissembling it to locate the trouble. The dealer came back a few days later to report the trans was non-rebuildable and had to be replaced in total. There were no parts and no rebuild data available from the Germans. By that time the transmission was partly dismantled and the specialist called me to come take a look at what he had found. He pointed to a shaft and bearing seated in the housing.

Normal practice during assembly of a transmission would be to press a roller bearing unit onto the shaft. The shaft and bearing would then be slid into a bore in the transmission housing until the outer race of the bearing seated against a machined shoulder. Then a circlip or snap-ring would be pushed in expanding into a machined groove to prevent the bearing from coming back up the bore. With me so far? Hope so.

Now here is what was found. During manufacture the bearing and shaft went into the bore in the normal manner, but there was no machined shoulder. The entry into the bore featured a tapered lead-in. The outer race of the bearing had a groove machined into it for the snap-ring. There was a corresponding groove machined in the bore. So, during the manufacturing process the shaft and bearing (with snap-ring fitted) were pushed into the bore. The taper compressed the snap-ring and then it traveled along the bore until it found the groove whereupon it expanded, thus locking the bearing into place. This approach leaves no means to extract the shaft and bearing without damaging either the bearing or the transmission housing or something else in the way (or nearby).

The dealer informed the owner of the car that she would need US$8,000 plus tax for a new transmission. Fitting and calibrating would obviously be extra cost on top of that. So, her car was worth less than the transmission alone. She happened to arrive right at that point and broke down crying when she was told the great news.

To cut a long story short she still has the car, but it no longer has a German heart. We were all so disgusted we did a surgical transplant and dropped a Japanese engine and transmission assembly in there. Brett machined up a new badge for it. It reads “Toyodi” and the car is the ” model JT” (for “Japanese Transplant”). Now this was not a straight forward job to do, but not as difficult as may be thought. Nevertheless it cost her a fair wedge of cash (although not as much as a new transmission from Europe). She got off relatively lightly though, and this for several reasons.

One, it was a Friday afternoon and after work there was beer.

Two, once suggested this was a project that was just too good to let it escape. And, did I mention the beer?

Three, she is a nice person who didn’t deserve what had occurred.

Four, we showed the car to the dealer for fun and giggles.

This turned out well, but there is a concern that as time goes by the Japanese makers are heading into the same philosophy as the Europeans. I sure hope they all stop. Perhaps the up-coming major recession may well be enough of a change of environment and values to change certain attitudes and approaches.

Meanwhile, be careful you only purchase that which can be conveniently and enjoyably repaired.

Si

Hi Si,

Yup. Unfortunately. A good friend of mine runs a shop; so I know this story, too. It was extremely excellent of you and your crew to help that lady out.

Word about these ticking time bombs needs to spread.

Better yet, the diesel version-if you can find them with the 6.2. All the advantages you speak of plus good fuel economy. Cold weather is the downside

anchar, the 6.5 Turbo diesel is a great engine. Good fuel mileage, starts in any weather and all mechanical, not a computer in the pickup. ’92 and ’93 only. ”94 up were electronic. For whatever reason GM does one off type of things, it was packed with sound deadener, quiet too. Nice seats in the captain chair models and mucho room inside.

You are, unfortunately, so right.

We as humans pine for the simpler, and younger, times, because that is where we assembled ourselves as well into the people we are today. Our minds and perspectives were also more nimble and able and things consequently just made more sense.

It is not the brave new world of technology that we should despair over, it is the loss of our own horizons and aspirations.

The latest lot of human beings will likely have a future where they also look back upon how much simpler things were.

I know the feeling…that’s what I did with my ’68 Olds Delta 88. I had a great base to work with: Rocket 455 with C code heads, Turbo-400, big engine bay…swapped the original 2-barrel for a Toronado lo-rise intake and Q-jet, added factory dual pipes, a hotter cam with specs along the lines of the “Apprehender” police package, put in a shift kit and Ignitor II electronic ignition…and turned a sedate luxury coupe into a real sleeper.

I recall having one of those 8 way wrenches. Don’t know where I got it, maybe a gimme but it was in my toolbox(not boxes). I was doing a tune-up on my cousin’s ’68 Vette with a 350. There was the distributor but how in hell did you reach the hold down bolt on it? Then I thought of that wrench, stuck it down there, twisted the ball to get it just right. Hhhhmm, this is evidently what they made it for.

I augmented my income automotively going to college. I was the go-to guy for head jobs. I always timed by sound and driving. Once it knocks, back it off till it doesn’t, perfect tune. Sometimes a harmonic balancer would spin in itself so timing marks didn’t mean anything anyway.

“I recall having one of those 8 way wrenches. Don’t know where I got it”

Probably Western Auto. I remember how my hometown WA store smelled, like new tires and gun oil. Bike shops still have those dogbone 8 ways, or Agee’s here did lasttime I was in there a few years ago.

I have a timing gun, not sure why, I use the same method you describe and it always comes out better than with the gun.

“not sure why” I guess if the timing was way off, you could use the light to get close, and then ‘fine tune’ from there.

I’m pretty pedantic about this stuff (timing, etc.) and so use the light to baseline and then fine-tune.

eric, there’s so much most people don’t understand about timing. Dwell comes to mind. On the new pointless ignitions playing with the weights and springs is an art. It’s best done with machines that you can spin it and watch how it advances and retards and at what rpm. I used to get a guy with those machines to set up my distributors specifically for the engine. It’s not easy to tune it to the particular cam, CR, and a virtual plethora of other variables. Most people also don’t know removing the areas of where the connecting rod was cast will greatly improve it’s strength. I still use a triple beam scale to make each rod as close as possible to the same weight(tenths of a gram)as well as pistons and their connecting parts. Take as many wrist pins as needed and weigh them. I never find an ending point till I have every single part identical including every part of the cylinder and port matching and smoothing runners. It’s too involved to mention everything but that’s the way I like to wrench. I bead blast con rods to strengthen them and make them the same size. I would never consider not getting valve spring to the same poundage of spring rate. If I had the machining and measuring devices I’d be building $30 K engines simply from measuring and adjust everything that can be(everything)done on an engine. I haven’t gone the titanium rod route yet due to finances but they’re getting affordable.

As far as any moving part, lighter and stronger is always better.

I once had 3 different timing lights on hand to compare on the same motor (at the same time obviously), a snap on, a craftsman, and some Harbor Freight cheapy.

Assuming the snap on was correct (but who knows?) the HF one was 2 deg off and the craftsman was 4 deg off ….

I keep in mind that the reading I get with the light is relative and try to get the final timing using best mph -2 deg at the track.

Those were great days. I cut my teeth with tools by working on cars with one of my brothers. Sis got a 3 yr old 77 Newport ex copcar that had a shaking engine. We took the heads off and took them to Hiway Auto Parts for a head job. Heads were cracked. They gave us 2 used W2 heads, did the head job, and we put it back together. Engine purred like a smooth pussy(cat). Took the car out on the freeway and did 120 mph in just a few seconds. My youngest son today is 21 and he knows so much more than I did at that age. He fixes his friends cars and teaches them about cars also.

The only way for a real young man to grow up then. But not today and the men today are like girlie pussies.

Another big plus, cars were much better looking and easy to distinguish from a distance. And colors – real colors – not various shades of dark bland or gray or white. No one confused a Chevy or a Ford or a Plymouth, nor corporate siblings with each other. Even in the dark.

Right on the money. We bought a silver Subaru Forester, and are forever losing it among a sea of silver SUVs. It’s annoying.

I once approached a lookalike SUV and tried to unlock it with my key before I discovered the error. Fortunately no alarm on that car went off.

Those were the days. I grew up at the tail end of that era as well. I never got past adjusting timing and flipping the air cleaner over, but I learned to turn a wrench or two as required.

I miss those days. In the 1980’s you really couldn’t modify much, but Japanese cars were fairly easy to work on. Today, engines are covered in high temperature black plastic. It takes an act of congress just to change oil.

Today sucks.

Child of the 80’s here too. And like you I didn’t get that far into working on my car other than what it takes to keep one going.

My first car was a 74 Firebird with a 400 in it. I had some good times in that car, and it really stuck out from what most of the other kids were driving back then.

I love Eric’s articles when where he waxes nostalgia about these old Pontiacs because it really hits home for me. Makes me really nostalgic for our gold Trans Am bought strait from the dealer back in the 70’s.

Good times!