Well, no – it’s not what you thought. This column isn’t about Caitlyn (nee Bruce) Jenner. It is about your car’s transmission. About pros – and cons. And about how to make it last as long as the rest of the car – whether you go automatic or manual.

Which is more important than it used to be because of the stupefying cost to rebuild – or more often, replace – a late-model car’s transmission. In some worst-case scenarios, it can cost as much as the car is worth. Or close enough to what the car is worth to make it hard to justify the fix.

Automatics and manuals have different weak – and strong points. And there are specific things you can do (and ought to avoid doing) in order to get the maximum possible service life out of each type.

First, the weak – and strong – points of each.

Manuals are inherently simpler – and simpler usually means more long-term reliable. For instance, they are much less vulnerable to sudden catastrophic failure resulting from overheating or fluid loss (which we’ll get into shortly).

Most of the time, they cost less up front, too – because the manual (when available) is usually standard while the automatic is optional – and so costs extra.

Also: If you have a manual transmission, you can roll-start the car if the battery ever dies on you. This is because there is a physical/mechanical connection between the rotating wheels and the rotating engine. When the wheels turn, so does the engine – assuming, of course, the transmission is in gear and the clutch is out (once the car is rolling). If so, it will turn over just as if the starter motor were doing that job and if the ignition is on, the engine ought to fire. This physical connection between the engine and the rotating wheels is why, by the way, you have to depress the the clutch – or keep the transmission in neutral – when the car isn’t moving but the engine is running.

Otherwise, the engine stalls – because it can’t turn over the Earth!

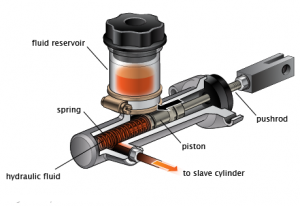

You can’t roll start a car with an automatic because the connection between the engine and transmission is hydraulic. If the engine isn’t running, there is no hydraulic pressure and so the car just rolls. The engine has to be running to produce the hydraulic pressure that runs the automatic and – in turn – turns the drive wheels.

So, if you have an automatic and the battery dies, you’re stuck until you can find someone to jump-start the thing.

Automatics, on the other hand, are easier when the battery isn’t dead. No having to clutch – or shift. An automatic can just be left in Drive – and the engine won’t stall when the car isn’t moving, either. (The hydraulic connection allows some slip, which is why you can keep the transmission in gear when the vehicle isn’t moving and the engine is running.)

While manuals can be fun on the open road, and do give the driver more control than an automatic, they can be a chore in stop-and-go traffic. Also, they wear faster when subjected to stop-and-go driving. Clutch in, clutch out – and in-between. The clutch is a wear item. And it wears out, just like brake pads do. The more you use it – like brakes – the faster it wears. Replacing the clutch is part of routine service with a manual transmission and should be factored into the decision about which way to go. A clutch job generally runs between $500 and $800 depending on the vehicle.

On the other hand, manual transmissions themselves (i.e., the gearbox) are less maintenance-fussy.

Usually the only thing they need over their service life is very occasional (about every 75,000 miles or so is usual) changing of the gear lube/fluid – and they are generally less finicky about change-outs than automatics, because it’s just lube for them while for an automatic, the hydraulic fluid is the lifeblood of the transmission. It literally works like the blood in a human circulatory system, pumping and pressurizing the internals. When the tiny orifices in the hydraulic circuit – which are analogous to arteries in a human being – become clogged by particles or varnish (result of not changing fluid and filter in good time) the effect is a lot like clogged arteries in a human circulatory system.

That’s the general lay of the land. So – how to get the longest life – and the fewest repair bills – out of each?

Automatics:

Three things are absolutely critical.

One, never let the thing run hot. Unfortunately, this can (and does) happen pretty often because many cars do not have a transmission temperature gauge and some don’t even have a warning light. Which makes it hard to know when the transmission is running hot . . . before it’s too late to do anything about it. Overheating can destroy an automatic in minutes. Which is why shutting down and getting off the road before too many minutes go by is so important.

As a general rule, if the fluid temperature exceeds 240 degrees, the life of the transmission will be shortened. As a general rule, 190-220 degrees is considered normal operating range.

Assuming your car’ cooling system is in good shape and you are not subjecting the car to excessive loads (such as towing more than it is rated to tow on a hot summer day) you shouldn’t have to worry about this. But it is smart to know about this – and even better to know for sure.

Be aware that a factory-installed dashboard warning light – an idiot light – may not come on until the transmission is already running hot. A gauge is preferable for this reason and worth adding, if your car did not come with one from the factory.

If you notice your transmission is running hot, find out why immediately. And stop driving the car right now. It’s inconvenient, but much less expensive than buying a new/rebuilt transmission.

Two, never let the transmission run low on fluid. Which – if it gets too low – will lead to rapid overheating and catastrophic failure.

Check the fluid level on the dipstick regularly – once every two weeks, at least.

And check under the car every day for signs of leaks.

Transmission fluid is usually reddish – unless it’s really old, in which case it will look like old engine oil but it will be much thinner, almost like water.

If you find more than a drip or two – or a new drop or two – find out why. And check the level immediately – before you turn the engine on. If you find more than a couple of drops – if you find a small puddle – do not turn the engine on. The running engine will pressurize the hydraulic circuit in the transmission, making the leak worse. Do not drive the car. If necessary, have it towed to a shop to fix the leak. A hassle? Certainly. But a tow – and fixing a leak – is usually much cheaper than a new transmission.

Three, change the fluid and filter per the service schedule. Do not skimp on this service . . . unless you want to buy a new/rebuilt transmission long before you otherwise would have had to.

Fresh/good transmission fluid – as mentioned above – is usually ruby red; if it’s brown or black – and smells burned – you have problems.

Or soon will.

Manuals:

When you first start the engine – especially on a cold day – gently let the clutch out with the transmission in neutral and wait about 30 seconds before driving off. This will circulate lube within the transmission. This happens automatically with an automatic – but not with a manual. If the car has been sitting overnight, all the lube will be in the bottom of the transmission and not circulating on the moving wear parts. By letting the engine idle with the clutch out (i.e., engaged; the shifter in Neutral, of course) you’re letting the lube circulate – and warm up, which (on cold days especially) will make the transmission easier to shift and reduce wear and tear.

Regularly change the fluid in the slave cylinder reservoir. All cars with manuals built since the ‘80s have one of these. They were added to make clutch engagement easier – via hydraulic assist – and to make the clutch last longer (by reducing wear and tear). Pop the hood and you’ll see a small fluid reservoir near the brake fluid reservoir. This is the slave cylinder reservoir – and it’s filled with brake fluid (hydraulic fluid) just like its bigger brother.

Replacing the fluid on schedule is important for exactly the same reason that it’s smart to change the brake fluid regularly. But even more so because if you don’t, the slave cylinder might fail prematurely – rendering the car undriveable. And In some cases, replacing the slave cylinder means pulling the transmission.

This is not a cheap date.

Drive smoothly. This one’s obvious, but important nonetheless. Abruptly releasing the clutch will result in more rapid wear and tear – and so will riding the clutch, i.e., keeping it partially engaged. Avoid grinding the gears. The more smoothly you shift (and clutch) the longer the transmission will last.

. . .

Got a question about cars – or anything else? Click on the “ask Eric” link and send ’em in!

If you like what you’ve found here, please consider supporting EPautos.

We depend on you to keep the wheels turning!

Our donate button is here.

If you prefer not to use PayPal, our mailing address is:

EPautos

721 Hummingbird Lane SE

Copper Hill, VA 24079

PS: EPautos stickers are free to those who send in $20 or more to support the site. Also, the eBook – free! – is available. Click here. Just enter you email in the box on the top of the main page and we’ll email you a copy instantly!

It’s more like $2,000 for a clutch job on an engine where they have to pull the whole thing out. My ’07 Accord would still be with me, otherwise.

Every operation of the clutch takes it closer to breakdown. Professional truck drivers know that the only reason for the clutch to be operated is to start the truck rolling. After that, floating will spare the clutch from excessive wear.

One thing I do in my manual transmission cars is shift to neutral for long stops at red lights or traffic jams. Some cars like my 77 Spitfire are susceptible to pilot bearing wear, I feel this helps them last a little longer. On older vehicles, especially Triumphs, switching the clutch fluid to DOT 5 makes the system last a long time as DOT 5 will not adsorb water or remove the paint off the firewall if you spring a leak.

On a big rig this causes your left boot to wear out and some days, your leg too. Last week I noticed the left boot had a different feel from the right. Time for new boots.

If you are headed downhill, all you need is the brake. If gravity will do the job, let the clutch rest.

Seems like I’m always headed uphill. A couple years ago I was hauling rock from a pit on a hill. You could release the brake, roll through the pit and out onto the hiway before catching a gear. In that particular truck I only had to blip and get sixth and go on. When I’m rock hauling to a location it seems like there’s lots of clutch holding waiting for pieces of equipment to get clear.

I’ve never hauled out of a pit that was downhill outbound. Almost every road out of a bentonite mine I used to haul out of was, causing truck with their brakes set to slide towards a poorly bermed roadside. I lost traction coming in one day, and the only thing that prevented my belly train from going over the berm was the pup turned sideways. We stopped taking the steepest road in after that. It took a huge loader to drag that belly train out of the road.

Bill, normally it’s a hell of a climb out of a quarry but this was stockpiled on top of the ground. No DOT so we were filling belly dumps to the brim.

You can tell the operators of loaders and graders aren’t truckers by some of the dangerous roads in and out of pits. I’ve had some hairy ones I wasn’t thrilled with. I once talked the guys into opening an old road they had closed for no good reason I could see. It was a big relief for every trucker. The people who make these roads don’t realize how close a truck is to being overtaxed on them. One exit was so steep you had to stay in a really low gear and I’d lock the diff’s to cut down wear on the drivers.

If your employer ran belly trains, I would be surprised if the grade wasn’t why they didn’t use them there, especially if there was no DOT around. I routinely grossed over 135,000 when I was hauling bentonite 25 miles round trip from the mine to a processing plant.

There’s some understanding problems here.

The torque converter fills via the transmission’s oil pump as one adds fluid with the engine running and trans in park or neutral. First add several quarts before starting engine, then keep adding until trans is full, Cycle through gears as fullness approaches so you get the servos, etc. filled.

Interesting about converter drains. they were once standard, but for some time now only Mercedes has them. It’s a nice feature since you can do a complete fluid change without the waste of fluid involved in using a flush machine. I don’t know, but suspect that automatics used on heavier trucks,buses, and industrial applications probably have converter drains.

Erik, you’re right about the pump filling the TC but only in neutral since the pump isn’t engaged in Park. That’s the reason for putting your transmission in Park when trying to cool an overheating engine. You are cooling the coolant Only and not the trans. fluid also. Also most applications measure a quart more when at running temperature. Some transmissions used to have a puke tube if they were over-filled but I doubt any are made that way now.

Hydraulic clutch systems no longer have their own reservoir. They share with the brakes.

Another reason to stay with 20 year old or older vehicles. The saving grace one day was when my old dual mass clutch was so hard to push for such a long time(I never noticed till a friend with a body shop moved it and asked how big my leg was)it blew the line to the slave cylinder. At that point it was just a matter of starting in gear and driving 60 miles home without it, no big deal.

I bought a truck with a new clutch and didn’t think anything about it. 80,000 miles on it and all of a sudden it wouldn’t disengage so I drove 500 miles back to the house stopping once on the steep side of a hill(gotta piss and get a drink)and started it in 1st, a really low gear just fine for an empty rig. Sure enough, it had only worn a few thousandths before the disc plates springs got into the intermediate plate because they were installed backward. It’s just too much trouble to read “This side to Engine” on the damned intermediate plate. I’ve never had clutch problems with big rigs or much of anything else except very high horsepower cars and not much there. I’ve blown more transmissions and rear-ends than clutches.

Some do and some don’t.

Where is the hydraulic reservoir on a Freightliner?

Bill, go back to usenet in 1997 if that’s the game you enjoy.

This is isn’t EPcommericaltrucks, it’s EPAutos.

Like I’m the only commercial driver here? Maybe you should start EPputz.

What you do for a profession is irrelevant to the context of the thread and we both know the game you’re playing.

Do you even shag boy bro?

http://www.thepostgame.com/blog/dish/201409/bill-murray-shares-about-caddying-boy

It is very hard to drive a stick when in a traffic jam because of all the people driving automatics. They have no problem stopping and tailgating, so instead of crawling along at 2-5 MPH they just stop and start. Very hard on the clutch and the driver’s nerves.

This unfortunately is just so true. My car idles at 4mph in 1st and it would be much more convenient if all the automatic drivers didn’t feel like getting 10 feet ahead of someone else was of paramount importance. I just moved to DC in June and good lord the drivers are aggressive here. It’s definitely not as much fun to drive a stick in the District or NOVA but I drive so little (only 100 miles in August, 200 in September) that I’m not getting rid of this car.

Hi District,

You have my sympathies, amigo.. I worked in DC for ten of the most brutal years of my life. Well, until I got divorced…

There is less wear on the “clutch and the driver’s nerves” if the clutch is only used to begin movement instead of starting and stopping.

I drive to the City (NY mostly, sometimes Jersey), and have to deal with Traffic, fortunately my exhaust is loud (didn’t realize it when I bought it) so all I have to do is Rev and it wakes people up

Another thing about manuals, don’t use the shifter as a hand rest. It causes excessive wear on the shift fork(s). I just refreshed a tranny that I’d had for a few years in a beater Miata. It was always tricky getting it into 4th. You had to make a brisk and firm gear change for it to go in. When I took the 3/4 fork off it was worn nearly half way though on the 4th gear side…not the raised pad area, the entire fork. I’m surprised it would go in 4th at all. I guess the momentum on the slide ring was enough to make it hook up.

I recently blew the rear planetary on my 170k mile 4l60e (drag racing w/slicks didn’t help), rebuild cost $1070 out the door. I was pleasanly surprised that it didn’t cost significantly more.

link to informative thread on trans flushing, it’s 4l60e specific but applies to most auto trannies I think.

http://www.impalassforum.com/vBulletin/5-drivetrain/252894-should-you-flush-your-trans-fluid-if-hasnt-been-maintained.html

Two things I see a lot are people covering the brake with their left foot while driving (brake lights on) and others using the clutch pedal for a footrest. With any automatic I have owned, if you hit the brake pedal hard enough to illuminate the brake lights (even though the brakes aren’t grabbing yet) it will not allow the torque converter to go into lockup. This will increase the heat buildup and could lead to premature trans failure. Resting your foot on the clutch pedal is no good because the weight of your leg + bumpy roads is going to slip the clutch by varying amounts. Increased wear – premature failure, blah blah blah.

Dirty, do you know if drilling a hole in a torque converter and installing a plug is viable in the transmission in a 2000 Z 71? I’m about to change fluid and filter after 60,000 miles on a flush. I’d like to get all the old oil out if possible. I’ll take a line loose and use compressed air to drain the cooler. I’m sorta anal about “clean” on any filter.

I removed the fuel filter on a 60 Series Detroit one day and had to use a filter wrench to spin the ring off the filter housing. I removed the ring and cleaned the threads on it and the filter body. When I put it back together I could tighten it tight enough with just my hands as it was intended. People often don’t watch the finer points of fluid replacement. I’m big on using remote full flow and bypass filters on engine oil. I believe I’ll try a bypass filter on the transmission line too.

My vehicles are operated in what the factory calls “extreme” conditions…..really dusty and sometimes muddy conditions every time they’re used.

Sorry Eight I don’t know about the drain plug thing, I don’t do any major transmission work. Only thing I would worry about is throwing off the balance on the converter….

In the thread I linked above they say you can achieve the same result with a DIY fluid exchange via the cooler lines, just may burn an extra quart or two to get it all passed through.

also see: http://www.hotrodders.com/forum/drill-torque-converter-thread-plug-drain-completely-110066.html

Dirty, thanks for the link. I’m not trying to overthink installing a plug. Using an Allen plug could change the balance such a miniscule amount I wouldn’t worry about balance, just what I might contact drilling through.

I’m fairly certain drilling into the back corner of the converter is safe not letting a bit go further than necessary. Anyway, I think I may have answered my own question with the Allen wrench plug(and some red Loctite).

How are you going to refill the torque converter after it’s drained? You can try pumping the fluid in through the drain hole, but a lot of it will run back out unless you have a sealed adapter to screw into the drain hole. Also, no way to tell that you’ve filled the TC back up with enough fluid. Every TC I’ve ever seen, you fill through the opening where it connects to the transmission shaft. I think you’re gonna have a rough time trying to do something like that. It would just be easier and better to remove the TC and turn upside down to drain it. That would involve removing the transmission too because I don’t think you could get enough clearance to slide it out even if the flywheel is removed. At least that’s been my experience working on my cars in the past.

Turd!

Dammit, man… where have you been?

On the rest: I’m with you. I would not add a drain plug for just the reasons you cite and one more. It may be unlikely, but it is certainly possible that the addition of a drain plug would cause a rotational imbalance unless compensating weights (like lead wheel weight clips) were added. It is also possible you’ll have a clearance issue if the bell housing is really snug. How much would that suck – once you drilled the hole, I mean.

My 50 on this is that if you regularly change the fluid, just dropping the pan and replacing that appx. 60-75 percent of the fluid volume plus a new filter will be enough.

Or, you can be anal (just for you) as I am. And install a T fitting in the cooling lines and drain the works. But this is more involved and requires carefully monitoring how much is coming out and putting just enough back in… until the whole system is full of fresh fluid.

If I remember correctly (please note this is my standard disclaimer…), back in the early to mid 70’s GM cars came with drain plugs in the TC. The TC was balanced with the weight differential and the flywheel plate the TC attached to had holes to allow access once the rock shield was removed. Later versions of the TC had the starter ring attached directly to the TC body.

To refill the fluid? Best way I found was to place the car in neutral, connect a pump to the cooling lines while adding fluid through the dipstick tube. Of course, one would need to know the specs for the trans capacity with and without the TC fluid change.

Of course, as a caveat (as noted above), I am 64 and suffer from some-timers, sometimes I remember things correctly, sometimes I don’t.

NoneYaBiz

Hey Eric & guys…I’m still kicking it around. Just been really slowed down ever since that car wreck a few years back. I’ve still been hitting the site regularly, just been lurking more than commenting. I had no idea you guys actually missed a piece of shit like me…sniff sniff. I’ll try not be be such a stranger in the future. Hope everyone here is doing well.

Turd, I wondered out loud(well, typing)not long ago how you were and what you were doing. We miss you Turd. You have the most creative avatar….bar none.

Think of the scene in Hangover 3: We miss you Chow. You miss Chow?

” I had no idea you guys actually missed a piece of shit like me…sniff sniff.”

Ahem….I’m not gonna touch that line. Hey, Turd. I had a bad wreck too, in 2015. Looks like you and I are the gimps in this bunch now. Don’t be a stranger.

Turd, what up bro? I guess I hadn’t thought it out all the way. But I’ve drained a Ford with a plug and let it fill from the pump when started.

eric, what you suggest with a T is a good idea. I was considering getting a fine by-pass filter to go in-line. I thought about calling Joe at Amsoil and see if they have a by-pass filter that will full flow except for what the filter uses.

Reading about how new oil makes crud turn loose and sends it back into the system was something I hadn’t considered either. That makes a 1 micron filter that won’t slow down the flow sound better all the time. It also explains why some people might be right in worrying about changing fluid on a malfunctioning transmission. I never considered new fluid exposing the unit to old build-up but it makes sense.

OTOH, it’s been 4 years since the Cutlass transmission began malfunctioning and replacing the filter and installing Amsoil synthetic fluid not only made the unit work correctly but stopped a leak. The fluid looked fine and the filter wasn’t bad at all leading me to believe jobber no-name fluid it had in it might not be the best, esp. since it had 50,000 miles on it…..but that was nearly twice what is recommended under “severe” conditions. Everything on the place operates under those conditions.

I have to wonder if everything in Tx. doesn’t operate under those conditions for most of the year. I know everyone doesn’t operate in as dirty conditions as me but a clean cooler/radiator shouldn’t be any different than a unit operated in a cleaner environment.

Dammit, cars and pickups are made to such sorry specs I’m always considering the primary and secondary filters on oil and external coolers on transmission lube and how much better that would work on pickups….which mostly have external filters and coolers these days. When GM first installed temp gauges on their Allison transmissions behind a diesel it gave me hope.

Now if I could only get a pickup with a fuel pressure gauge, a boost gauge and a pyrometer I’d likely never have a surprise.

Rebalancing the torque convertor would be the most difficult part of the project.

Manuals have one other huge advantage over automatics – they force the driver to pay attention to driving and use all four limbs to operate the vehicle.

Distracted driving becomes very difficult.

I guess they don’t write manuals for paraplegics?

Hey Eric,

What is the downside to not using the clutch after first gear?

Hi Tuanorea,

If you are a Master and can time the shift perfectly, none!

Aber, this is a high art not much practiced these days 🙂

eric, the bad part about it is the synchronizers are so good and have been for so long it’s impossible to tell exactly where the shift point is. Now synchros like big rigs have is another story and it’s not hard to tell at all. On a decent transmission a good driver can changed gears and it just looks like he’s simply pushing levers willy-nilly but he’s doing a dance that’s often so intricate, especially with dual gearboxes, that most people would be shocked to get stuck behind the wheel and figure out how it’s done.

I’ve done it to the point I inadvertently reach for the shifter, if there is one in the floor when I’m driving a car or pickup when starting up a grade or falling off onto a grade. My wife is always slapping my hand as I reach out for a gear that isn’t there. It’s frustrating for me too, esp. driving a diesel pickup. You become so attuned to shifting when an engine reaches upper teens that you will try to shift when there’s no gear to change to. I couldn’t tell you how many times I’ve been in OD in a pickup and reach over and move the shifter into neutral and then realize I don’t have another OD gear….Ah shit, I’m likely to say before returning it to the last hole. I guess that’s why old truckers are always looking for another hole.

Do the same thing myself, reach over to get OD(wtf?) that’s all we have.

On roll starting automatics we had a 59 Chevy with a Powerglide,Folks were too cheap to change oil or buy a rebuilt starter, you could get her up to 30 -35 mph, rolling or pushed and it would turn over and start when you pulled the shifter to low range.