Driving a simulated car – as in a game – is becoming more and more like driving an actual car – in reality.

At least in terms of the inputs.

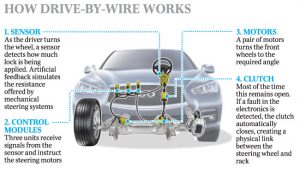

The car in the game is steered remotely, via a gamepad. You accelerate and brake the car the same way. Soon real cars will be accelerated and braked the same way. Many already are, at least as far as acceleration. They have drive-by-wire throttle control. Your foot does not actually control the acceleration of the vehicle. A computer controls the acceleration of the vehicle. It assesses data it receives from sensors that are connected to the accelerator pedal, but there is no physical connection between your foot and the throttle.

The good news is the throttle cable can’t stick with drive-by-wire. There is no throttle cable. The bad news is that the computer can “stick” – accelerating the car even though you haven’t pushed down on the accelerator pedal. Even if you’ve taken your foot off the accelerator pedal entirely.

The car industry denies this happens but there is more than a little evidence that it does or at least, has – and regardless, the fact is it can.

The problem is – what to do about it?

Which brings up related questions about other forms of drive-by-wire, including drive-by-wire brakes and steering, both of which are more than speculative problems. They are both in the works, part of the technical development of automated cars – which (ultimately) won’t have steering wheels or brake pedals – or pedals at all, for that matter.

But they are also being contemplated for non-automated cars; I.e., the cars we control. Except, we don’t, really. See the above in re drive-by-wire throttle control. We ask the car – the computer which really controls the car – to perform in a certain way. To accelerate full-on when we floor the accelerator pedal, for instance. But the computer is the Decider.

It can decide to do something . . . else.

Just as in principle (and technical fact) it could decide to do something else with regard to braking and steering the car. And if that happens, there is literally nothing you – the driver – can do to countermand it since there is no physical interface between you and the brakes and the steering wheel.

Two scenarios present themselves, both extremely plausible.

The first is simple wear and tear on the bits and pieces – and the connections. And the sensors and motors that control the operation of these systems. They will be exposed to dirt and moisture, to high heat and extreme cold. They will experience vibration and shock – from hitting potholes and such. There will inevitably be defects or at least, design weaknesses that do not manifest right away – but will manifest eventually. And there will be hiccups and failures related to wear and tear.

All of the above happens to current physical connection systems, too. But total loss of control is extremely rare. You might get a shimmy or vibration through the steering wheel when suspension/steering parts are worn; the car might pull to one side if it is out of alignment. If you lose the power steering pump (or the belt which drives it) steering effort will increase, but you will not lose the ability to control the car’s direction.

What happens when – in a drive-by-wire steering system – the car jerks hard to the left and your attempt to correct via countersteering has no effect – because the computer refuses to recognize you inputs? What happens when there is no steering wheel at all?

With current physically-connected brakes, you might lose partial pressure (the systems of all cars built since the mid-1960s have separate front/rear hydraulic systems precisely to eliminate the possibility of a complete failure) but mashing down the pedal will cause the car to slow down and stop, eventually.

But what happens when the computer doesn’t want to apply the brakes?

Or, when someone else doesn’t want it to?

This is the second scenario – a hacker accessing the car’s computer and causing it to accelerate when you want to stop. Or steering it off the road. This is all within the realm of the technically possible.

Which is pretty damned scary.

Particularly given the fact – as this columnist has observed before – there is no mandate for a fail-safe, an electronic-age version of the Dead Man’s Pedal which locomotives used to have. Some way for the driver to seize control – if it becomes necessary – from the computer.

This is a safety issue, certainly. One with potential consequences at least as serious as backing up over a kid or having an under-inflated tire blow out at high speed. And yet, no call from the Usual Quarters for “action.”

One wonders, why?

. . .

Got a question about cars – or anything else? Click on the “ask Eric” link and send ’em in!

If you like what you’ve found here, please consider supporting EPautos.

We depend on you to keep the wheels turning!

Our donate button is here.

If you prefer not to use PayPal, our mailing address is:

EPautos

721 Hummingbird Lane SE

Copper Hill, VA 24079

PS: EPautos magnets – they’re back! are free to those who send in $20 or more to support the site. Also, the eBook – free! – is available. Click here. Just enter you email in the box on the top of the main page and we’ll email you a copy instantly!

Have you seen this:

https://www.theguardian.com/technology/2018/mar/20/uber-self-driving-car-crash-death-arizona-elaine-herzberg

Bert.

Answer: Because they would prefer centralized control.

The principles of statism require that the state, or its henchmen, have actual control. Over all things. And the technocrats designing these vehicles are working hand-in-hand with their statist overlords to give all the control to the overlords.

The move in this direction is now going at hyper-speed. I place the beginning when Overseer Ray “The Hood” LaHood, Transportation Department Overlord, issued a fatwa against hand-held communications devices after a high-school student in Missouri causes a multi-vehicle accident on I-44 near Joplin, MO, because of texting while driving. This occurred in 2010, I believe.

His fatwa doesn’t accomplish anything immediate. But car manufacturers then start developing on-board communications systems.

In 2014, Congress passes a crap sandwich of legislation written by Barbara “Boxhead” Boxer that required all vehicles built after the 2016 model year to have transponders to connect to NSA built-in and always on, allowing for continuous, real-time monitoring of all vehicle locations within the United States.

Then when Florida was threatened with hurricanes last year, Tesla announced that they would “allow” vehicles in the storm’s target area to be allowed to operate at 100% of capacity, so that the operators would be able to safely escape the storms. Why were they not allowing their battery packs to operate at 100% before? I don’t know, but it doesn’t make sense from an individualist point of view.

And soon, we will have to tolerate sitting in the (driver’s) seat of a vehicle that we can’t have full operational control over?

To quote the late Congressman James Traficant (D-Ohio): “Beam me up!”

The circuitry that controls the charging of batteries runs from just enough to that which can manage batteries more effectively than any human lacking a laboratory. The lives of most types of rechargeable batteries is reduced by always charging to “100%” instead of using the technology in use to maximize life instead of episodic performance.

It is totally irrelevant what Tesla does because Musk has always made more money from reloaning his company money he got for almost nothing from the government. Between that and the subsidies that Tesla receives, the making and marketing of cars is a loss leader.

“Why were they not allowing their battery packs to operate at 100% before? ”

Because they decided to make one battery pack. But the cells and such are expensive so normal companies don’t populate the entire pack with cells for the lesser versions. Apparently TM did. Software company thinking?

BTW someone had to pay for all the extra cells in the battery packs of the cars that didn’t have owners who paid for the extra range. Either the people who ordered the ‘option’ of the “larger” battery pack paid for extra cells for everyone or everyone paid for them option or not. A software switch can’t use something that isn’t there.

Eric,

I drove a lot of International tractors while I was doing driveaway. When their brake pedals would get and stay wet, the fulcrum would rust and the brakes would stick. This lead to me leaving a trail of hot brake smoke on a couple of occasions. A dab of penetrating oil being applied at each service would have prevented the problem.

Why would a rotary encoder be more or less likely to stick than an accelerator cable?

It looks like we’re all going to HAL in a handbasket.

Where we’re going, we won’t need hands…

Looking for a bright side to all this…. when our masters decide someone needs to be taken care of, or say be suicide’ed, instead of the whole operation involving a number of spooks and others, just login to the guys car, and its taken care of….. imagine the savings for the taxpayer….

Hi Nasir,

I love my Trans-Am all the more on account of this…

eric, you used to hear them say wire was heavy but components that are not connected by wire aren’t necessarily that much lighter. The REAL reason it’s being done is to save labor. If they wanted to save weight and increase mileage they could stop putting those huge wheels and tires on everything….esp. pickups that it’s just a liability on.

The last round in the patch saw those pickups with a ruined tire on lease roads just because of some 1.5″ rocks. Don’t know if the girlie-boys that drove them were simply too much wuss to change the tires but abandoned pickups were common.

Lo-pro tires on big rigs are just stupid if you have to get off pavement.

Here you on that – one of the saddest things is when I see an amazing SUV or truck on lo-pros. Reminds me of an image of an elephant in ballerina shoes or something similarly comic….

Hi Eight,

Yes – and also to increase labor costs. There is much less “wiggle room” with components tightly fitted, with harnesses that cannot be spliced/repaired. Just throw away – and replace – with new parts.

Speaking of wiggle room, I’ve been pondering the myriad failures of our educational system here lately, and the issue of mechanics versus “technicians”. I’ve had a young “technician” (kid is not a mechanic by any stretch of the imagination, and certainly not a machinist) helping me out with going through my ’58 F100 and doing some modernization for daily driver/shop truck duties. Every time we run across issues of parts not having perfect fitment, he automatically assumes it is a defective part and has to be returned. He about lost his mind learning about having to ream the kingpin bushings.

Slowly I have been teaching him that sometimes we might have to take a file to a part, or put it on the Bridgeport and fit it to the truck. This was still being taught to us in the late 80’s-early 90’s when I was in shop class, so what the hell happened? We used to know that a tolerance of +/- .025″ or more might be between parts, and we might have to file, mill, or shim things to get them square. Hell, my 84 K5 Blazer has better than ½” of shims under the left front fender from the factory.

A machinist has never been required to work on anything that a mechanic changes parts in. It sounds like you are making custom modifications on a vehicle that hasn’t been made in many decades instead of finding someone to supply the standard parts which are still available, in some cases, from the local auto parts store. If you need a machinist, you will have to hire a machinist and pay a machinist to do the job instead of hiring a marginally experienced wrench turner to do the job.

Hi El Guapo,

Yup! It seems “technician” came into vogue along with computer-controlled systems. Once could not pull a code from a vehicle such as your F100. And you’re right about less-than-perfect fitment with older stuff, too. Fine-adjustment (even shimming) was part of the protocol. Of course, that also meant needing a bit ore skill/experience than it takes to pull a code.

What I like best about the older stuff was exactly that it was more amendable to mechanical adjustment, as desired. Today’s stuff often either works – or not.

Would love to get a car like that at some stage in life…. which is just a pure and simple car, doing what a car is meant to do….

Hi Nasir,

I’ve had mine for 25 years now, which is probably why I have it. 25 years ago, these cars were still affordable; they aren’t anymore.

Already happened:

https://en.wikipedia.org/wiki/Michael_Hastings_(journalist)#Controversy_over_alleged_foul_play

I play a-lot of driving video games and they all have the same flaw. They all oversteer. Every single game I have tried has the same stinking problem. Its’ disappointing every time I try a new game and that problem continues to persist. Its scary because it will largely be the same people who will be designing these systems for real cars soon. Frankly “driving” virtual cars are far more difficult then a real one.

And to be frank, software is terribly glitchy. It can crap out for no reason at all, including a well maintained one. Software is the weak link in modern electronics of all things. It will have to be far more robust before its going to be trustworthy. It not even close yet today.

If we get malevolent smart AI, imagine what could happen if every car on the road – or parked – simultaneously tries to take all of us out.

¿cuán simulación deben tener los autos?

¿por qué no la simulación total? nada más que píxeles y bits. es más barato y más seguro de esa manera.

¿hablas una lengua libre?

http://fiatlingua.org/wp-content/uploads/2017/12/fl-00004E-00.pdf

Ours is not to question why, ours is but to do (and)or die.