Here’s the latest reader question, along with my reply!

Mark writes: My 1995 Subaru would run well, then sputter, then run well, without any prediction. The feeling I had behind the wheel that that the ignition advance was all off, to the point of the spark being retarded. A retarded spark feels much different than, say, a single plug misfiring. The retarded spark affects all cylinders and it feels like the whole engine is cutting out, rather than a weak hiccup resulting from one cylinder. So anyway, I searched the ‘net and found a thread that said to look at the knock sensor. When the knock sensor goes bad, it could cause rough running, is what it said. After more research, I came to know that the knock sensor is a piezoelectric resistor simply bolted to the top of the engine. (As is the case with the horizontal four layout of the Subaru.) When the knock is detected, the resistance of the piezoelectric device goes lower. The thread said a workaround is to replace the sensor with a 552k Ohm resistor. Since my car is so damn old, workarounds such as this are just fine. However, I ended up buying one on eBay for $15, a genuine Subaru part besides.

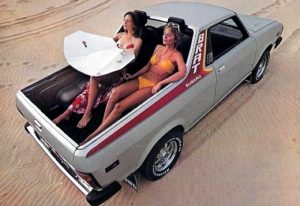

When I went to go and replace it, I noticed that the wire off the sensor was nicked! So, if this was getting shorted out, then that would cause the issue. The wiring off the sensor was all stuffed down in there, so I relaxed that, taped it up and vroom! No problems. I have some pix of the sensor, the nicked wire, and a glamour shot of the “old girl” herself!

Keeping the old iron running is especially nice here in VA, with the damn car tax. It is zero for the old girl. I wholeheartedly agree with your assessment that mid 1990s to early/mid 2000s are the apex of car design. That Subaru is very tough, very easy to work on, and simple. Only drawback is, as a ’95, it does not have OBDII. I have a nice OBDII scanner and can display live data, etc., which helps vastly with troubleshooting. Anyway, if you think you readership would be interested in this, you are welcome to use it. Thanks!

My reply: I love stories like this – and fixes like this! I’ve experienced a few similar in my life and have learned to start with the simplest thing and proceed from there; sometimes you get lucky – and it is a simple thing.

Your Soobie was built at the apex of Subaru – when simplicity/durability/value were prime directives rather than virtue-signaling about saaaaaaaaaaaaaaaaaaaaaaaaaaafety. I myself would love to have an ’80s-era BRAT – remember those? rear-facing seats bolted to the bed? The children! Think about the children!

Saaaaaaaaaaaaaaaaaaaafety!

. . .

Got a question about cars, Libertarian politics – or anything else? Click on the “ask Eric” link and send ’em in!

If you like what you’ve found here please consider supporting EPautos.

We depend on you to keep the wheels turning!

Our donate button is here.

If you prefer not to use PayPal, our mailing address is:

EPautos

721 Hummingbird Lane SE

Copper Hill, VA 24079

PS: Get an EPautos magnet or sticker or coaster in return for a $20 or more one-time donation or a $10 or more monthly recurring donation. (Please be sure to tell us you want a magnet or sticker or coaster – and also, provide an address, so we know where to mail the thing!)

My latest eBook is also available for your favorite price – free! Click here. If that fails, email me at EPeters952@yahoo.com and I will send you a copy directly!

A troubleshooting technique that has served me well with computer controlled engines is to disconnect sensors one at a time. When you find the sensor sending false signals the brain will use a known safe value and the car will run better. With ignition coils misfiring disconnecting the offending coil will make no difference while disconnecting a good coil will produce a miss and change in rpm. This simple diagnostic procedure can be done by anyone. My ditz of a sister had a multiple misfire on her VW. Dealer wanted to replace all 5 coils at astronomical cost. She performed the pull and replace on every connector she could see and found the crank sensor was the culprit. She searched the part number stamped on the component and replaced it herself.

Squirrelly,

That doesn’t sound very plausible. Crank sensor connector is underneath the car by the bell housing. If the skid plate under the engine is still present she would have to remove that also. Disconnecting while the engine is running would shut the engine off.