If you like to work on cars you probably hate crawling around underneath one, trying to get at things you can’t easily reach – or even see. This gets old after awhile. In my case “awhile” turned out to be decades – which is how long it took for me to finally say enough to crawling around under a car.

I decided to get a lift for my garage. But which lift? More finely, which type?

The latter was effectively determined by the limitations of my garage. I decided against getting a two-post (or four post) lift – the type most people are familiar with, that you see in the work areas of car repair shops – because my garage does not have a shop-high ceiling and so I would not be able to raise my truck or Trans-Am high enough to make full use of a two-or-four-post lift, defeating the point of getting one.

There was another consideration that steered me away from a two-or-four-post lift:

The posts.

These would need to be permanently bolted to the floor of my garage to secure the lift – and when the lift was not in use would have stood like metal totem poles on either side of one of the two parking spots in my garage. That would have made it awkward to walk in between my truck and Trans-Am and made it difficult to park one of my bikes in between those two.

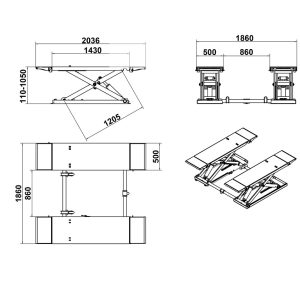

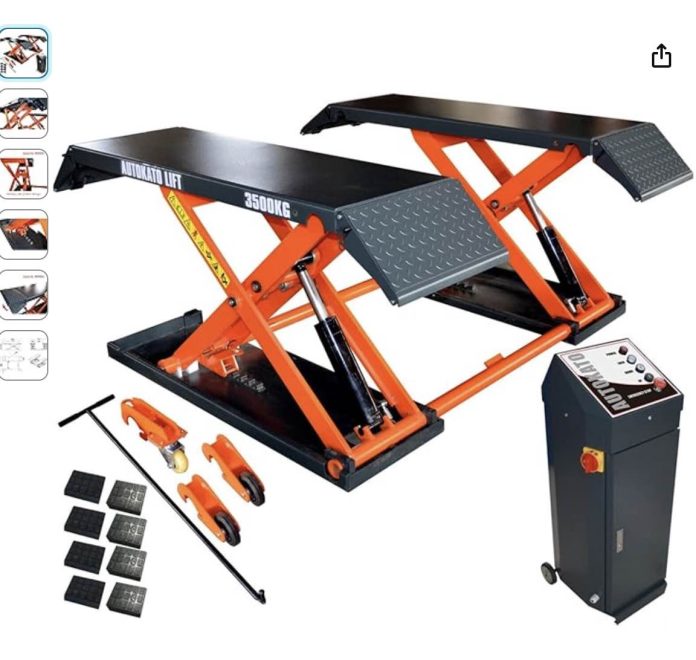

So I decided on what is called a mid-rise scissor lift, the Autokado X80. It is ideal for me – and might be for you, too.

First, it takes up almost no space when it’s not in use. It folds down, accordion-style, onto its own footprint, which is a square roughly 5×5 or so with ramps on either side that you drive onto and park your vehicle over. There are no posts on either side.

Second, it raises a vehicle high enough to sit comfortably underneath – which makes it much easier to see what’s underneath and get to things underneath. I have already done two small jobs that would have been a big pain-in-the-ass without the lift. The first was to change out the gear lube in my truck’s (manual) transmission. This job entails removing the fill plug on the side of the transmission case and the drain plug on the bottom of the case. (Voice-of-experience tip: Always remove the fill plug first – to make sure you can remove it. If you don’t – and drain the lube/fluid first – you might not be able to replace what you just drained.)

Without a lift, getting at the fill plug is a big pain-in-the-ass. So also adding fresh lube. It entails writhing around on your back, trying to get at what’s hard to see and even harder to reach. With the lift, this job was easy and even fun.

As wrenching ought to be.

The other job I did was to replace my truck’s exhaust from the catalytic converter back. Once again, this job would ordinarily have been a huge pain-in-the-ass as exhaust work always is when you can’t easily get at pipes, brackets and so on and move the various pieces around to get the fit right. With the lift, it was a snap. And – once again – fun.

Third – the lift is portable. You do not have to commit to a permanent site where the lift will sit once installed.

Because it isn’t installed.

The lift comes in one big piece, not counting the four ramp-extenders you install on the lift. It also comes with three detachable wheels that you attach when you want to move the lift. Just raise the scissors a little, slide the wheels on, then lower the lift. Now you can move it around as you would a pallet on a pallet jack.

Fourth, this lift is very ruggedly built and built with more lifting capacity (8,000 pounds) than I will probably ever need. My Trans-Am weighs about 3,800 lbs. and my compact truck about the same. This lift has capacity enough to lift a full-size pick-up, even a three-ton electric one such as the Ford Lightning – and I’ll never need to lift one of those, so I’ve got capacity to spare.

It is also safe – an important consideration if you are going to be underneath your lifted vehicle. It has heavy gauge steel crossbars and a welded-to-the-base ratcheting mechanism that is a reassuring failsafe in the event of a hydraulic failure.

The power unit is available in either 110V or 220V configurations, which is another thing I like and you may, too. Some lifts require the 220V hook-up that your garage may not have, in which case you would have to get an electrician to come out and wire one up for you.

Is there anything I don’t like about this unit?

Not yet!

There are some things to be aware of, though, that I want to make sure you are aware of. One thing is that because the lift isn’t permanently mounted, it can slide while you’re trying to drive up and over it. I discovered this the first time I tried to drive my truck over it. The fix is easy. I drilled four holes in the cement floor of my garage, two on the outside of each end of the lift (fore and aft). Into these I put threaded anchors into which I can screw in lag bolts that prevent the lift from sliding while I’m driving over it. These bolts can be easily unscrewed, leaving the flat floor as before.

And that’s all there is to it.

I had the lift up and running the day after it arrived (via truck freight).

If you’re sick of crawling around on the floor of your garage – but haven’t got a garage with a ceiling that’s high enough for a two-or-four-post lift (or that has enough room for the posts) you might want to check out one of these mid-rise scissor lifts.

. . .

If you like what you’ve found here please consider supporting EPautos.

We depend on you to keep the wheels turning!

Our donate button is here.

If you prefer not to use PayPal, our mailing address is:

EPautos

721 Hummingbird Lane SE

Copper Hill, VA 24079

PS: Get an EPautos magnet or sticker or coaster in return for a $20 or more one-time donation or a $10 or more monthly recurring donation. (Please be sure to tell us you want a magnet or sticker or coaster – and also, provide an address, so we know where to mail the thing!)

If you like items like the Keeeeeeev T shirt pictured below, you can find that and more at the EPautos store!

Nice solution with the bolts, but they’re already bent. It wouldn’t take much to cut some L angle iron and drill a few holes to, or better just weld up a bracket that will fit over the bars.

That way the bolts will do what they were designed to do. They don’t have much lateral strength, they’re fasteners.

3500 KG…that’s about 2200 pounds capacity. Is that the capacity of eich side or total capacity of the pair of lifts??

Hey William,

3,500 kg is about 7,700 lbs, referenced by Eric when he cites “more lifting capacity (8,000 pounds) than I will probably ever need”.

This is much more substantial than the one you wrote about earlier! I may have a 30×36 garage built this Spring. Was going for a tall shop style but near 100k for a 30×36 metal box with a concrete floor too spendy for me. So, this lift you picked fits the bill for a shorter ceiling. Finally found an independent guy quoted a decent price for the 30×36 stick built with three tab roof, but garage height not big shop height.

Here in WA it’s not easy to avoid the F U contractor price quotes!

You can build a 10x12x6 foot wide long tall ‘doghouse’ that will increase ceiling height above the two post lift, works. Allows for the top of the vehicle to have some more room up top. Have some stationary windows up there, they will let in some light.

Maybe only 8x10x4 will work, might as well have the room though.

12 foot walls plus 6 more feet of ceiling, 18 feet, will be plenty. 12 feet is not enough, makes you worry. You can punch a dent into the sheetrock up above, it happens.

Make sure it is structurally sound, bearing walls and such. Might need some steel work done. Then there is the junkyard for wrecked vehicles towed there, parts and salvage bidness too. People want to drive automobiles, they pay for the use and convenience.

You need one of those bigger air compressors for air-powered shop tools and lithium-ion power tools to remove lug nuts and other uses, airline hoses are kind of replaced there. Ventilate the exhaust, for mercy’s sake.

The dealership has more than likely 20 foot ceilings. More than 16 feet for sure.

Same for new Walmarts and grocery stores, more than 16 feet tall and probably 24 feet up there. Makes for a more comfortable shopping experience. It is psychological, not to feel like you are being oppressed by short ceilings. For real.

The overhead electric cranes on I-beam rails fit to lift the armatures from the hydro-turbines at hydroelectric dam houses will lift many tons. Gotta be 40 feet up there, easy.

The old ones are at the salvage yards, a good 25 feet in length. You have to see it to believe it. Nothing lasts forever.

Machine tooling and skilled labor has to survive, can’t just sell pencils and apples on Park Avenue. Don’t you dare sell any loosies, we’ll kill ya.

Plenty of knowledge in the hands of humans, don’t have to make it all fubar.

Blackouts will be a weapon, not an accident.

Having had both a Scissor Type and 4 Post Lift, the best solution for me was a Pit with a Rolling Scissor Type Jack (One could get two of these to lift all four Wheels).

Thanks for sharing your experience, Eric. My garage will be built soon, and this is one of the considerations to be made.

Very cool. Happy for you.

Good for you, Eric! This seems to be a great solution for your situation. I was at that crossroads a couple years ago and went a different direction. Luckily I had the space to put up a 2-post and it’s been a Godsend. The time saved in getting a car up high enough to work under with jack stands is worth it.

Be safe, we need you.

When reading your lift articles I am reminded of my youth: no garage, it’s -20 below, my truck was parked over gravel. Fun times!

I think I made it 15 minutes before I had to go back inside & thaw out my fingers before I went back out & gripped that cold cold wrench.

…I really like those cross member supports on that lift, very,.. anti-wobble, it seems.

Just from a quick look on your video, it looks well built.

…I wonder if there’s an adapter so it doubles as a motorcycle lift? Or, maybe it’s easy to fabricate one?

Thanks for the product recommendation. I definitely want a lift one day.

A little scissor jack will lift your vehicle on one side to change a flat tire, just have to be at the right spot, the arrow. If scissor lifts would fail, there wouldn’t be any.

Electricity saves the day, it will do all of the lifting.

A scissor lift to get up to 16 foot tall ceiling heights is similar in build. For 25 grand to 52 grand is the price range for one you would want to use. A small scissor lift is 4,000 USD.

Finished steel is expensive, don’t want to build your own, buy the scissor lift.

I once owned a 1963 Ford Custom, the vacuum modulator failed, transmission fluid was flowing into the oil pan. Bought a modulator, you ask questions first, talk to a Ford mechanic, they know from experience.

I had to grind down the flat on an open end wrench to fit the gap between the engine area and the modulator. Replaced the modulator and problem solved.

looks like a could use one. looks like it would be a handy work table also

Wow, that looks like a great unit!

I still lay down on the ground and wonder what it would be like to have a shop lift while performing maintenance.

On a side note, post lifts usually require concrete floor modifications prior to installation, in order to achieve the proper thickness and strength.

Good luck with the AUTOKADO X80, ERIC…I want one!

Thanks, Frankie!

This thing has been life-changing. I just finished installing a custom exhaust on my truck – and it was fun. You can also justify the expense. A clutch job – if you pay to get it done – will cost more than half what this lift cost. So just that one job – done by you – erases about 50 percent of the cost of the lift.

All good points, Eric.

I was just looking at the cross brace piping that runs between both lifts; my thinking is to manufacture a thick plywood reinforced sheet that lays on top and tapers down on the front and back ends.

This would enable unobstructed rolling chair/creeper movement and also be comfortable on back if laying down is required.

The X80 looks like a quite a robust unit.